Jig Grinding

What is Precision Jig Grinding?

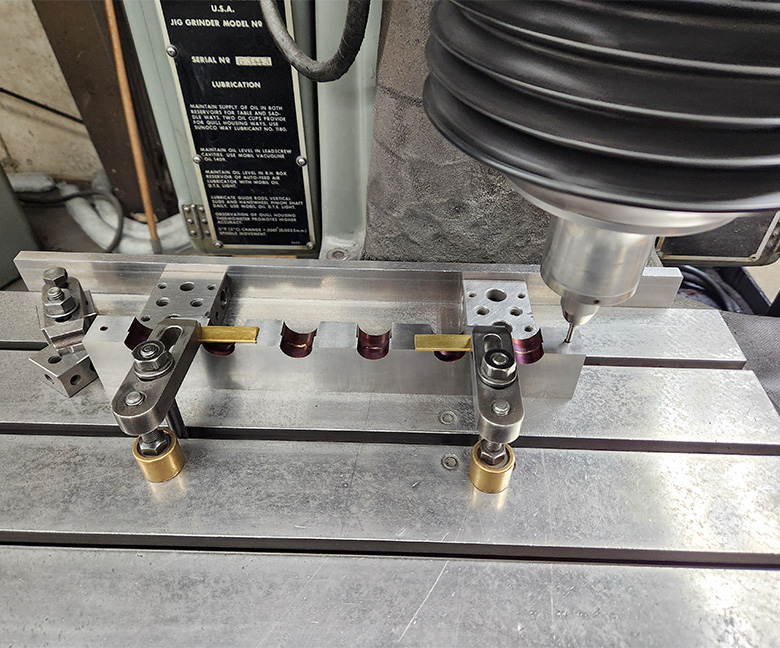

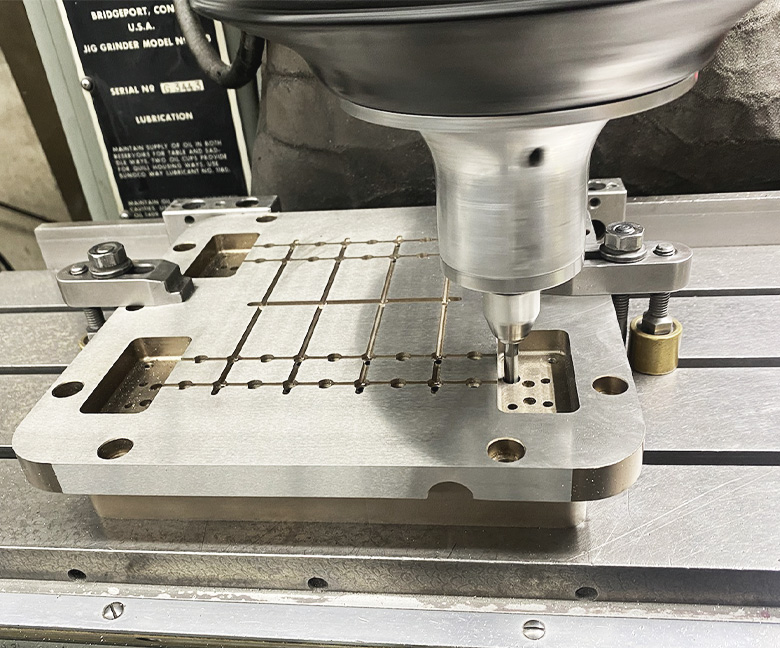

Precision jig grinding is a specialized machining process used to achieve highly accurate holes, contours, and surface finishes in components. This process utilizes a high-speed grinding machine with a precise jig or fixture to deliver tolerances as tight as a few microns. It is ideal for creating intricate patterns, achieving exact dimensions, or refurbishing worn parts with exceptional precision and smooth finishes.

What Jig Grinding services do we offer?

Hole Grinding – High-precision grinding for holes with tight tolerances.

Contour Grinding – Accurate shaping of complex profiles and geometries.

Tapered & Angle Grinding – Precision grinding for tapered holes and angular designs.

Repair & Refurbishment – Restoring worn or damaged components to specifications.

Custom Solutions – Tailored grinding for unique or specialized requirements.

Material-Specific Grinding – Optimized grinding for steel, alloys, and more.

Prototypes & Small Batches – Precision grinding for prototypes and low-volume runs.

Tool & Fixture Grinding – Accurate grinding of jigs, tools, and fixtures.

What are the advantages of Precision Jig Grinding?

- High Precision

- Smooth Surface Finish

- Restore Damaged Components

- Cost-Effectiveness

- Adaptability to Complex Tasks

- Custom Solutions

- Longevity

Our Process

Our jig grinding process involves using a high-speed grinding machine equipped with a precise jig or fixture to achieve highly accurate holes, contours, and surface finishes. The component is securely held in place, and the grinding wheel is carefully guided to shape the part to tight tolerances, often within a few microns. This process is ideal for intricate and complex parts requiring exceptional precision and smooth finishes.